|

| Case 430 Loading Logs |

|

| Case 430 Backhoe-loader |

|

| Case 430 in Agricultural format |

Shown here is one of 2 backhoe models that made Case a player in the emerging tractor backhoe business. This particular machine was built in approximately 1964. The first owner had wanted a diesel model, but he had a contract to dig footings for a paper mill and couldn't wait for the backordered diesel model to arrive. This machine came to the VanNatta's with about 600 hours on it, when the other guy finally got his diesel 530. The Case 530 was the most popular backhoe there was in the late 1960's. Case ultimately renumbered it to a 580 which is still marketed today.

The 430 was slightly smaller on a 40 Hp tractor with about a 10 foot digging depth. This model was essentially a Case Farm tractor modified for the purpose. A front drive hydraulic pump and an external frame were the main modifications. The canopy shown here is shop built. the 530 was a little more powerful with a hoe that would dig a little deeper.

Over the years it has seen a lot of service. Early on it installed septic tanks and drain fields and dug out springs and the like. With log forks on the front it loaded the first logs shipped from the Van Natta Tree farm in the mid-1960's. The backhoe dug thousands of yards of pit rock to rock many miles of road over the years. With over 30 years of service we now know what is wrong with these tractors. The most irritating is the brakes. They are an external disk brake with a band activator. They rust up and don't work right. The loader frame makes access and repair difficult. The generator/voltage regulator system has mostly not worked for most of the 30 years we have had this machine. The tach drive is on the back of the generator which discourages one from simply replacing the generator with an internally regulated alternator. Beyond that the machine has been very reliable. The engine has had one major overhaul in 30 years, but the rest of the drive train has required no repairs.

It is no wonder that this machine and its larger brother the 530 put case into the backhoe business to stay. John Deere and more recently Caterpillar have hassled them for market share but the solid reputation of Case made with these market opening machines has made Case a place in the market. Ironically, Case sort of came out of nowhere with this product. Before this machine was made, there simply were not tractor backhoes around, and Case was a bit player even in the Ag-tractor field. Then they made this machine and made themselves a player in the market to be contended with. They have since diversified their industrial equipment line, but this is where it all started.

In recent years it has been more of a yard crane than anything else. With a couple of chains, it is very handy for unloading freight. The front bucket will lift around a ton, making it very handy for those freight items that are too heavy to man handle such as truck tires and barrels of oil and many other things.

|

| Right axle removed |

|

|

|

| Drive axle |

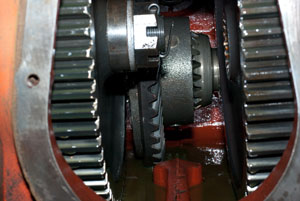

The task undertaken here was to replace a rear wheel bearing. This requires removal of the axle as the tire bolts to the end of the axle. The photos tell all. In this vintage of case, the differential is mounted inside the torque tube in front of the rear axles (actually the brakes on on the end of the shafts extended from the differential). A gear reduction behind the differential is then provided. The bull gear is what is visible in the gear box. For access you have to remove the PTO, or the PTO cover in this case as our tractor does not have a PTO. As you can see from the photos, the axle sticks through the bull gear and is splined to the gear and the bearings are held in position by a castle nut and cotter pin on the end of the drive axle.

The fascinating thing about this machine is how reliable it has been. As I write this in 2010 the Case 430 that we have is 45 years old. It was also an extremely early model. The first version with a hard nose and really made within a couple of years of the time that such a machine was invented. It's mostly been a few little things that have been the irritants over the years. Things that come to mind that have been issues are as follows:

|

Of all these things most are forgivable. My nomination for absolutely the worst is the unreliable brake design. The brakes have always from the time we got the machine either not held when applied or alternatively locked solid and jammed are requiring you to change directions to loosen them with disgusting frequency. It seems to be a design that Case was proud of because they used it for many years.

|

| 1997 JCB Skip Loader |

The real fault of this machine, if it has one, is that it is a little on the small side, which explains why for many years we also had an Oliver 1850 backhoe around. It, of course, was a little too big and a little to heavy which explains why the rubber tired backhoe market as stabilized with machines being made in a narrow size range a bit bigger than this Case 430 and somewhat lighter than the Oliver.

Indeed most of the backhoes now made are in the 14-19 foot digging depth and feature a 75-90 horsepower engine. , Case now features only 3 hoes all in the 14-16 foot range with 75-90 horsepower. John Deere has a wider range of machines as does Caterpillar who features about 5 machines in the 75-100 hp range. Ford-New Holland as well as JCB and Fiatallis offer a backhoes with the New Holland machines being on the lower end and and Fiatallis machine being a larger one. JCB has featured premium machines. This narrow range of sizes contrasts to the tracked excavator market which has all sizes which ranges from mini-excavators that can be pulled on a trailer behind a pickup to monsters that weight 100 tons.

These machines are sometimes called 'skiploaders' for reasons not to clear to me, but I suppose if you ever tried to load something with the scoop maybe you would have an idea about the name. The front loader is not as effective as it looks. This is particularly true with the loaders that lack 4-wheel drive. The problem is that when you try to scoop something, it shifts the weight off the rear tires which are the primary driving tires to the front wheels, and then not much happens. In recent years there has been a trend toward front wheel drive which helps a lot. Some manufacturers have used hydraulic drives for the front wheels while others have used a mechanical drive.

The other trend that has been visible over time is toward greater operator safety and comfort. First a roll over protection canopy was added and in recent years a fully enclosed cab with heaters and air-conditioning has been common.

The backhoe controls vary by manufacturer. Some use 2 wobble sticks for all functions while others use a combination of hand and foot controls. I've used both and prefer the combination foot/hand controls, but not everyone does. The case model featured here uses foot pedals for the swing and 3 separate levers for the boom, stick, and bucket controls. I find this very satisfactory, but the trend is toward joysticks that perform multiple functions.

This writers first introduction to the usefulness of a front end loader with with a loader intended as a manure scoop for the front of a small farm tractor. We had it around for 10 years before this Case came into the family and it did a variety of things most of which was not scooping manure.

Case, of course, started their ride in the industrial products business with their farm tractor model with a different paint job. They put a shuttle shift in the farm tractor along with an auxiliary hydraulic system run off the front of the engine. The loader frame itself served as the hydraulic tank.

But alas, over 30 years designs have evolved. Now no one would think of reworking a farm tractor to make a backhoe out of it. The units are designed for this use from the ground up. For example, the new Cat 'C' series backhoe loaders include such features as:

Probably the most recent addition in the trend is the rear wheel steering, actually 4 wheel steering. Logic changing is provided so you can steer only the front axle, or crab walk, as well as steer in a tight circle. This was pioneered by JCB and now seems to be a 'must have' on these machines. This come in ironic contrast to the 'skid steer' loaders which don't steer at all.

These machines are really the all purpose vehicle. We even fit our 430 out with a set of log forks and loaded logs with it for a couple of years. It would lift about a ton which worked for small logs. But with a set of pallet forks these machines make a credible forklift.