|

| All photos with blue borders expand if clicked |

|

|

|

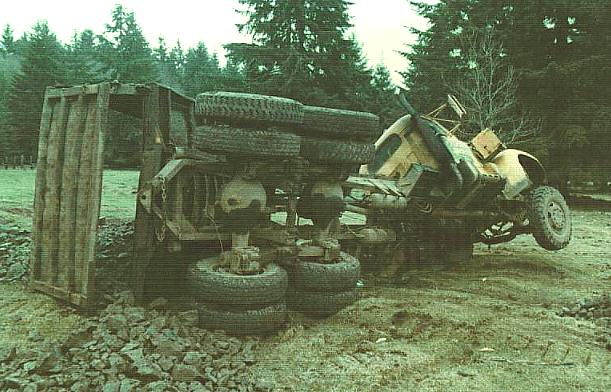

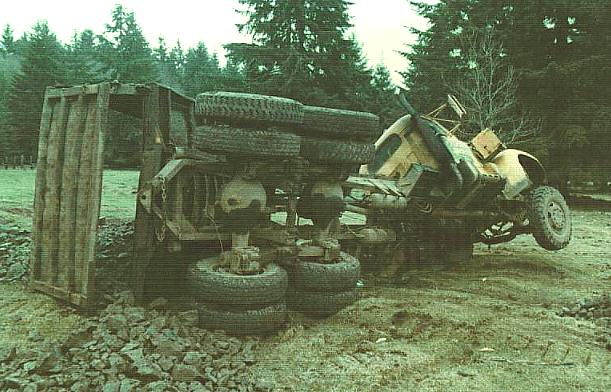

| Downside of a dump truck |

|

|

| Get on the Road |

One of the things that every logger must have is some roads which are usable. This means rock roads because it rains too much to expect a dirt road to be unable more than a month or two a year. Once you find some rock the next task is getting the rock where you need it. Dump trucks can be used but belly dumps are seeing increasing popularity. You see dump trucks have their problems (see photo). The problem with a belly dump off highway is only avoiding getting stuck. They are a bit of a disaster if matched with a highway tractor in an off highway application but they do nicely with a large 6X6 tractor.

There are a couple of popular types of belly dumps. The unit shown here is a windrow dump as the gates on the bottom open to the sides leaving the rock in a row in the middle. A cross spread trailer has a gate that swings to the rear allowing the rock to spread the full width of the trailer more or less evenly. The cross spread trailer usually does not open as wide at the gate so it has more problems passing oversized rock. The cross spread has the same problem as you have with a dump truck. by the time you chain the gate down to where the rock doesn't all come out in a pile the opening is usually 6-10 inches which makes you mighty unhappy when a 12" rock comes along. You can use a wider opening on the windrow dump because the gates are close enough to the ground that the rock really has no place to go so the windrow spreads out for a while no matter how loose your dump chains are. The good news of the off highway truck is that it has extra ground clearance so you can drive over the windrows. Trailers of this type with tandem axles usually haul 18-20 yards of material. The newer trailers tend to be longer to take advantage of bridge formulas and sometimes have triple axles on the rear to accommodate more weight.

As I said in the beginning, a big truck helps, but even they can spin out, and when they do and you try to back out of it for another run the trailer always goes downhill. That gets you in predicaments like you see here. Here we were rocking a fresh road going up hill which is very difficult, but when the pit is on the down hill side of the road, you either have to spread going up hill or clamber over everything and get to the top and turn around for a downhill spread. With a highway truck you can pretty much do neither which is why these things aren't that popular with loggers, but with an off highway truck you have a fighting chance, even though I lost out here and needed a tow. The push pad on the back is pretty standard because these things need that a lot. Unfortunately, when the trailer is over the bank as here, the push pad doesn't help. We finally managed to extract this situation with a Morgan Log skidder, but it pull really hard. We plan to start carrying a snatch block so we can put a block purchase on the the rig to get it moving.

For off highway work though, these older shorter trailers are to be preferred because shorter trailers track better on the turns which is forever an issue on crooked logging roads. This particular model features a '4 spring' suspension in the back instead of walking beams which is less desirable. Worse it has 'wedge' brakes which are a pain, but they can be lived with. The wedge brakes were somebodies better idea, but we are still looking for the guy.

Many a belly dump, including this one are made with a '4 spring suspension'. As the name implies, instead of having walking beams as is common on many trucks, there are well, 4 springs, which constitute both the 'suspension' and the flexibility for uneven ground. This effectively means that when you get on really uneven surfaces with the rear axles as is common on off highway usage, these rear tires range from off the ground to having the springs bent backwards and compressed 'to the stops'. As you might guess this is not the most durable solution for off highway applications.

|

The Page suspension is also pretty much the strongest type of suspension that I have ever dealt with. There are no springs to break and instead a triangular shaped fabricated walking beam. It's flexible enough that your wheels are all on the ground no matter how uneven the ground is. Needless to say, the walking beam suspension is clearly a better deal for off highway work.